Expansion Joints

TENSA designs and provides different types of expansion joints, which can be used in any structure. TENSA's joints are capable to absorb the structure movements caused by temperature variations, creep, shrinkage, seismic actions, from the smallest to the largest.

Key advantages

- Capacity to cover longitudinal and transversal movements

- Hard-wearing quality

- Possibility to replace it without closing the traffic and working actually on a part of the carriageway

Systems available

The UBJ is a rubber joint provided by inner reinforcing plates vulcanised together. UBJ joint covers nominal service movements from 50 to 360 mm (from ± 25 mm to ± 180 mm for installation with a nominal gap in average temperature without presetting). For seismic movements, this type of joints is able to cover up to ± 500 mm.

Request information

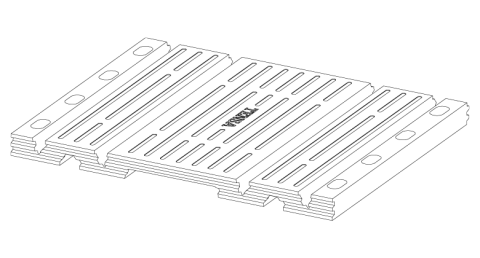

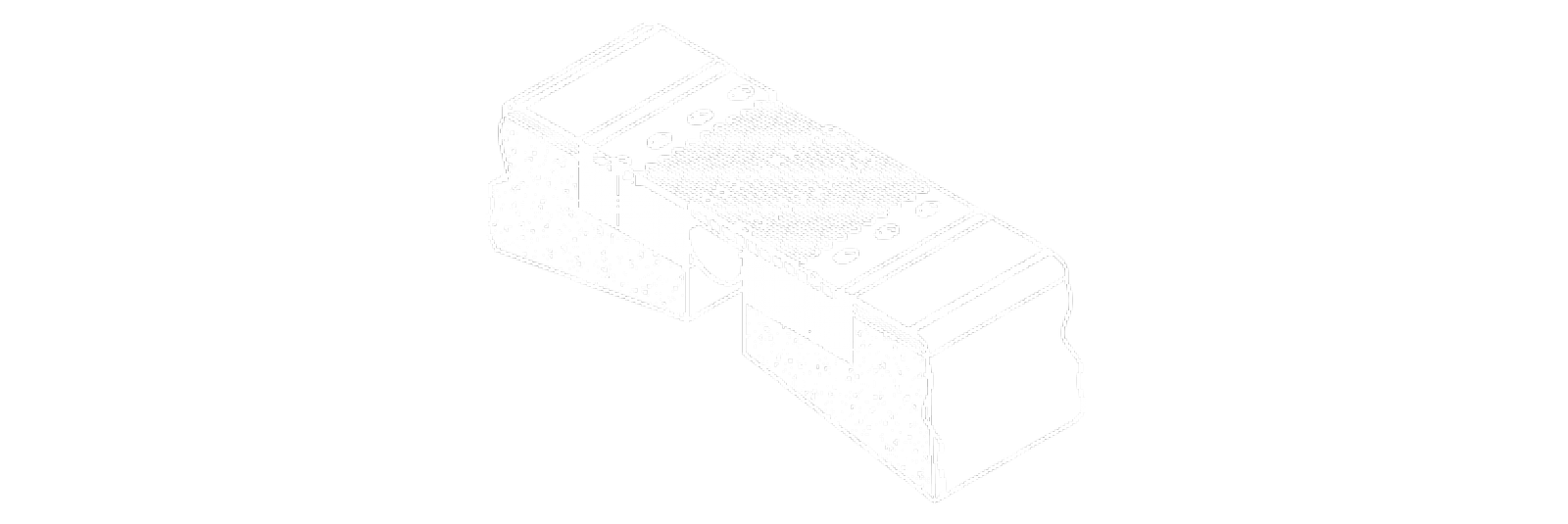

The MBJ is a modular expansion joint achieved by connecting one or two rubber elements to a steel plate. The latter is safely bridging the gap in any condition while rubber elements are accommodating displacements by deformation. MBJ allows movements from 400 to 1600 mm. The steel bridging plate has the upper surface machined in such way to increase the grip and to avoid possible aquaplaning effect.

Request information

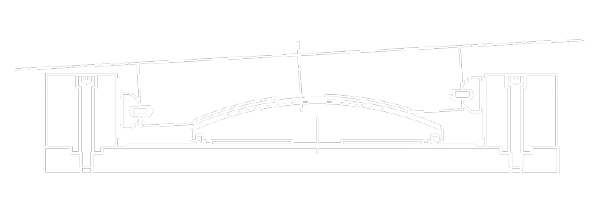

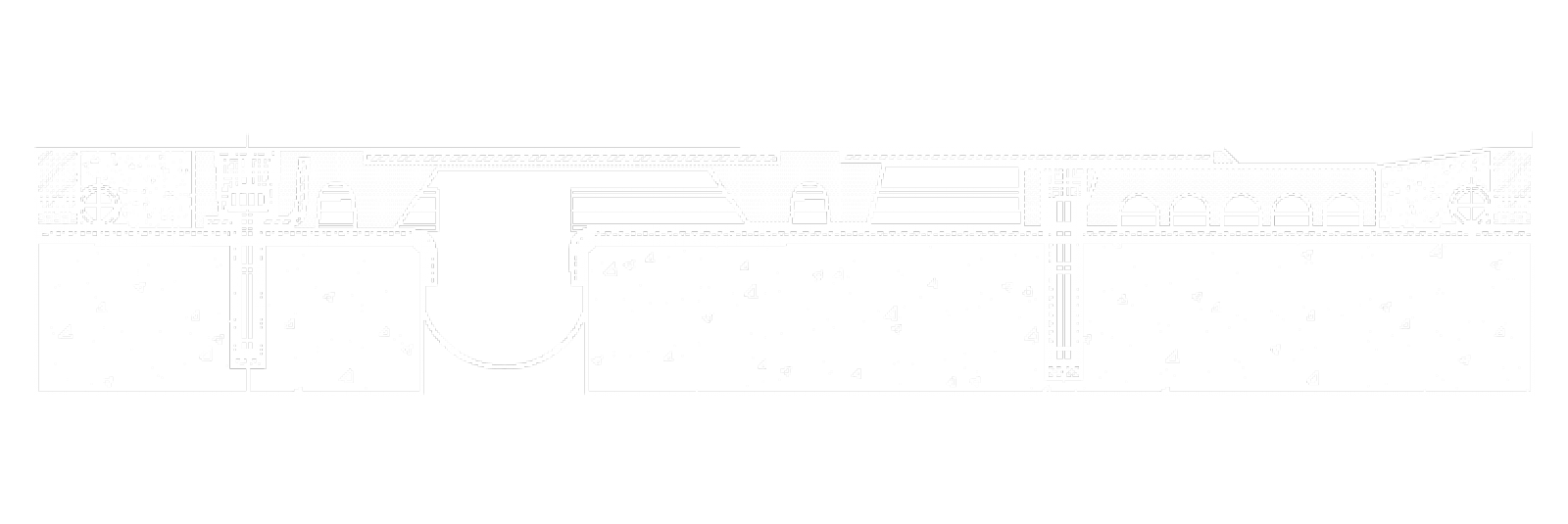

The SFJ is composed by two steel plates both machined to have a “finger” shape aspect and connected to the deck by stressing anchor bars (working as a cantilever). The elements are crossing each other and are getting closer or distancing according with structure movements. The joint accommodates movements along mainly one direction. They accommodate displacement from ±25 to ±1000 mm.

Request information

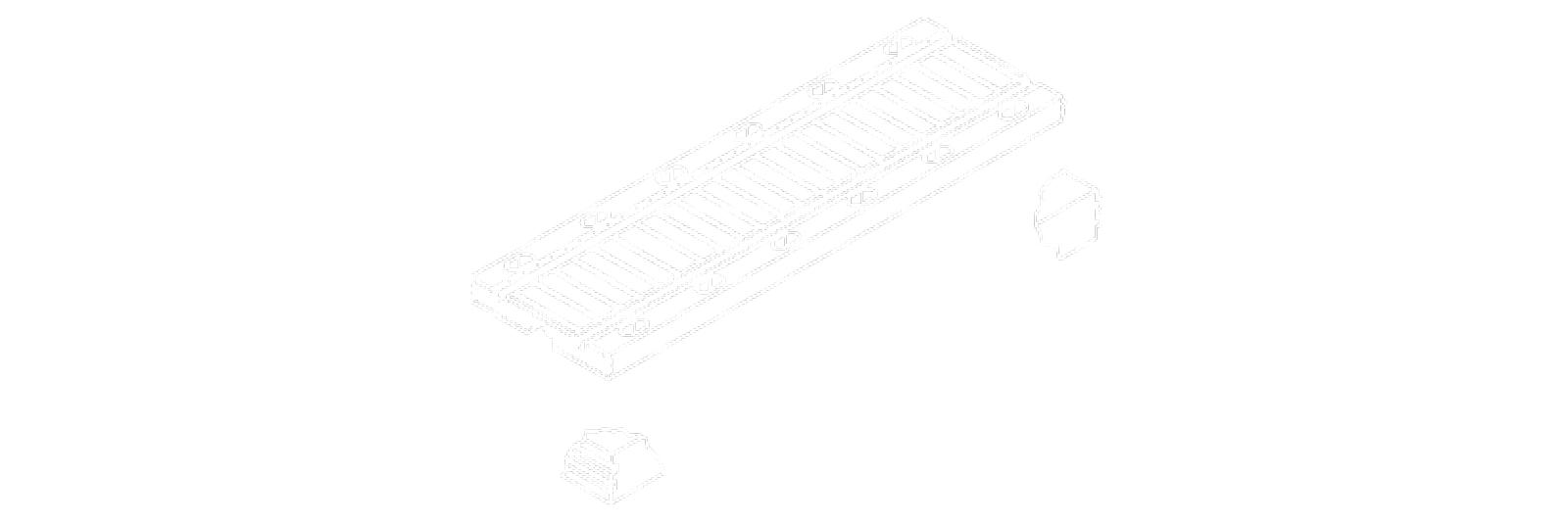

The RRJ has been designed for high speed railway viaducts being capable to work under ballast. The aim is to respect completely the specifications foreseen from RFI Technical Instruction (RFI is the Italian railway net authority). The movement is obtained by a crawling between an elastomeric surface and a stainless steel one and not by strains of the joint’s parties.

Request information